Background:

The mishandling of Diesel Exhaust Fluid (DEF) is an emerging threat to flight safety due to recorded incidents of its mistaken addition to the FSII dispensing reservoirs on refuelling vehicles, resulting in the delivery of contaminated jet fuel to aircraft. DEF is a urea-based chemical which is added to the exhaust streams of diesel-powered engines to reduce NOx emissions from the exhaust gases. Where an operation handles both DEF and FSII there is a potential for cross contamination. This risk is increased where both fluids are added to reservoirs mounted on the same vehicle. If DEF is mixed with jet fuel it forms crystalline deposits called clathrates. These deposits may accumulate on filters, fuel metering components, fuel system components or engine fuel nozzles and have caused engine shut-downs. DEF is commonly known as AdBlue®, Bluetec® or H2blu®. FSII is often known as e.g. PRIST® or ICE-5®.

The case for action:

Cross contamination has led to flight safety incidents including where engine propulsion has been lost (dead stick):

November 2017-USA: FSII reservoir filled with DEF – 5 Aircraft emergency landings.

August 2018-USA: DEF mixed into FSII reservoir after repairs – 2 Aircraft emergency landings. May 2019-USA: DEF mixed into FSII transfer container – 2 Aircraft emergency landings & 1 ‘dead stick’ landing.

Actions: This bulletin introduces new requirements in the JIG Standards.

- Operators shall implement effective procedures for receipt, storage, transfer and stock recording of all FSII and DEF held on location, including:Receipt documentationIn order to support traceability and segregation, receipt documentation shall be checked to ensure that the product and documentation supplied match the FSII and DEF ordered, and that all relevant documents have been supplied.

Container condition/labellingAll containers received shall be checked for appropriate labelling and undamaged condition when received. If not present or suitable, appropriate labelling shall be applied at this stage.

Recording of shipments and updating stock records

Records of shipment details, quantities received, stock levels in storage, quantities of FSII and DEF transferred to vehicle reservoirs and stocks in vehicle reservoirs shall be maintained.Disposal of used containersWhen an FSII or DEF container is emptied, immediately move it to a separate used container area and mark it as empty with the original material signage marked with a large “X” (the signage should not be obliterated so container residual contents can be identified and disposed of via an approved hazardous waste process). - Segregation, Storage and control of stocks There is currently no colour differentiation between FSII and DEF and no Industry agreed standard for selective coupling systems, therefore, operators shall implement the following controls to manage FSII and DEF.

- All FSII and DEF stocks shall be stored in separate and segregated storage areas.

- FSII and DEF storage areas shall be clearly labelled.

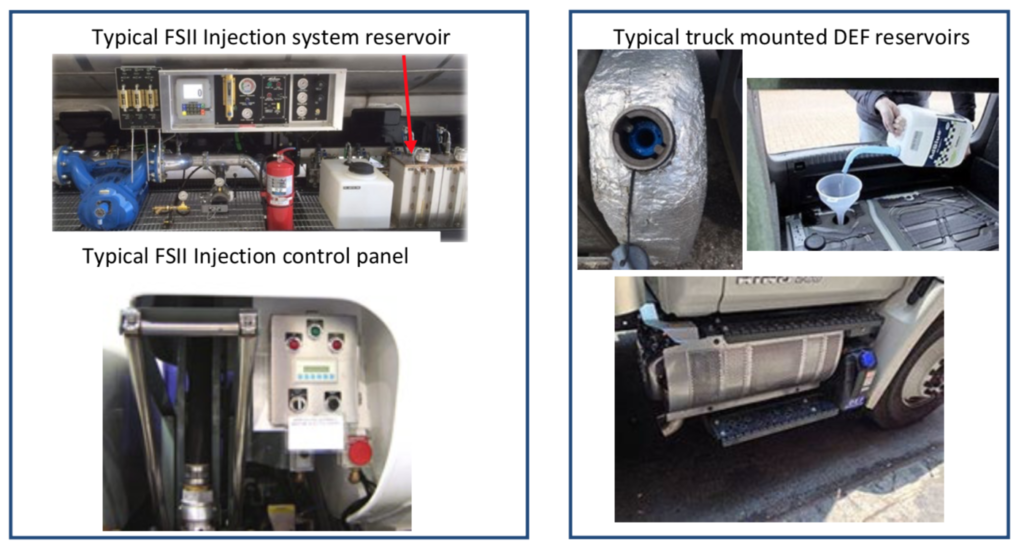

- Operators shall control replenishment of truck mounted FSII and DEF reservoirs using procedureswhich require a documented cross check and confirmation by a second person prior to refilling the reservoirs.Additional physical controls to prevent cross contamination shall include one of the below;

1. Lockable filler caps on truck mounted FSII reservoirs with keys held under controlled conditions. 2. Transfer of FSII through a grade selective coupling/adaptor on the transfer hose and thepermanently installed vehicle’s FSII reservoir. These selective couplings/adaptors shall be unique for FSII transfer at each site.

- Vehiclereservoirlabelling FSII and DEF reservoirs on fueling vehicles and transfer containers if used, shall be clearly labelled. A warning sign shall also be applied next to the fill point, clearly naming the brand of the additive stored in the reservoir, e.g. For DEF reservoirs: “Warning! Reservoir for {Brand of DEF} only” For FSII reservoirs: “Warning! Reservoir for {Brand of FSII} only”

- Procedures:All requirements listed above shall be subject to appropriate Management of Change plans and reflected in written procedures for the receipt, storage, stock control, handling, transfer and dispensing of FSII and DEF. There shall be separate procedures for FSII and DEF.

- TrainingProvide clear training, instructions and procedures to all relevant staff including fuelling operators and vehicle mechanics on;

- the potential consequences and risks to flight safety of the mixing of DEF with jet fuel and its effects, and

- the correct storage, handling, dispensing and control of both FSII and DEF.

Additional information can be found in EI1538- Handling of Fuel System Icing Inhibitor and aviation fuelcontaining Fuel System Icing Inhibitor.

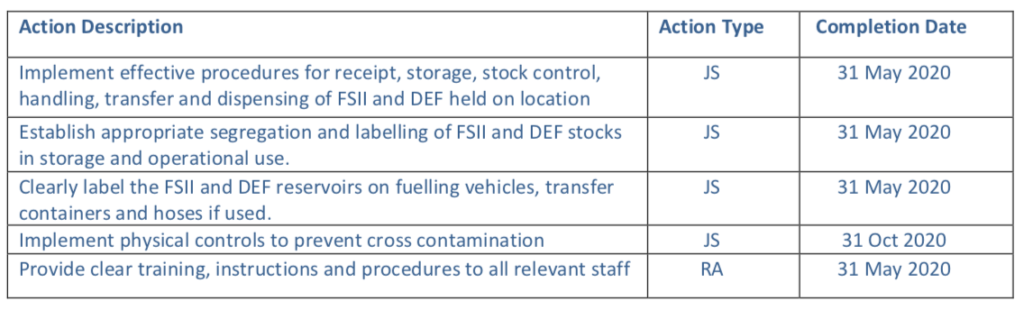

Actions to Implement this Bulletin (See Table 1 for Action Type Codes)

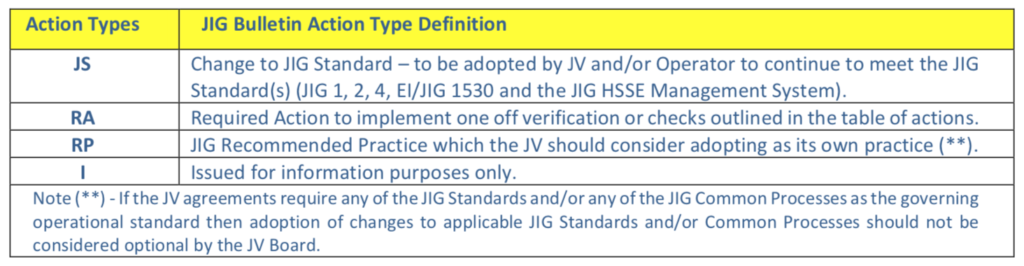

Table 1 Action Type Codes